-40%

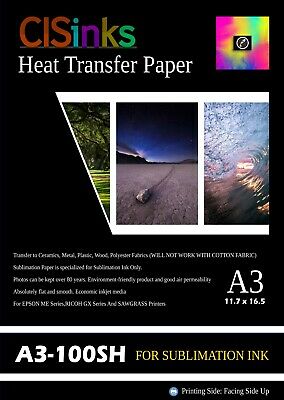

1Pack A4 Quick-drying Dye Sublimation Heat Transfer Paper for Plate 3D Printing

$ 8.77

- Description

- Size Guide

Description

新建网页 24-4 Color T-shirt Screen Printin

100 Sheets A4 Quick-drying Dye Sublimation Transfer Paper

Description

Quick-drying sublimation transfer Paper made in South Korea

Quick-drying dye-sublimation transfer paper for transfer on ceramics, textiles, cloth & fabrics with a specially coated surface. Do not use this paper with normal ink, Use sublimation ink only.

Feature:

Size:

A4 - 210mm X 297mm (8.3 inches X 11.7 inches) very close to a letter size.

Suitable Media: Light color Polyester fabrics, polymer-coated hard substrate ceramics, metals, woods, mouse pads ,cell phone cases, and Light color polyester fabrics mixed with no more than 50% of cotton, etc .

Printing Guidelines

Printing:

Image side is wound to the outside of the roll. Printing is performed in ″mirror″ image. Allow print to dry prior to transfer.

Printer & Ink Compatibility:

quick-drying sublimation paper has been tested and run successfully on most brands of inkjet printer systems equipped with dye sublimation inks.

Printers have all proven to provide excellent results with various dye sub ink manufacturers.

It is always recommended to determine the compatibility of the paper for use on

your printer and heat press equipment.

Printer Settings:

A Heavy Coated Paper print mode is recommended for all printer brands and models.

Do not over saturate the paper. It will result in bleed and will not enhance transfer color. The image often looks ″washed out″ prior to sublimation. Colors will intensify when transferred. Use ICC color profiles to optimize your particular printer/ink/RIP setup.

Material Storage:

To protect unused material, it is recommended to store material in its original

packaging, in the poly bag at 59-86°F / 15-30°C and 30-70% RH.

Only work with Sublimation ink, doesn’t work with iron on nor on 100% cotton t-shirt,

for best result should be 100% polyester.

Correct Using Quick-drying Sublimation Paper

1, Printing image on the rough surface coated by a special material, which can make the pressed result better.

2, Due to coating material on the paper, if the air is very dry, the paper will be curled a little. Generally keeps all paper into plastic bag, take around 10 sheets, turn the papers along long edge of the paper, (shiny surface is outside) put the papers in a mug, before printing, take one sheet paper from mug, bend the 4 corners of the paper to back (when printing, avoid printing head to touch the corner), put the paper into printer, printing immediately.

Or keep the rough surface down, and put a heavy object above it.

3, When before printing, please keep the shiny surface outside, then roll the paper, and keep for 10 minutes.

4, After printing, waiting 1 - 2 minutes for sublimation ink to dry, then make transfer.

hine

On Dec-04-20 at 19:27:20 PST, seller added the following information: