-40%

18 inch 450mm Diamond Grinding Disc 60-600 Grit No Hole Abrasive Wheels Lapidary

$ 79.19

- Description

- Size Guide

Description

450mm (18 inch) Diamond Grinding Disc 60-600 Grit No Hole Abrasive Wheels LapidaryProduct features

Outside diameter:

450mm (close to

18" inch

);

Thickness : 1.1-1.5mm;

Grit: 60-1000

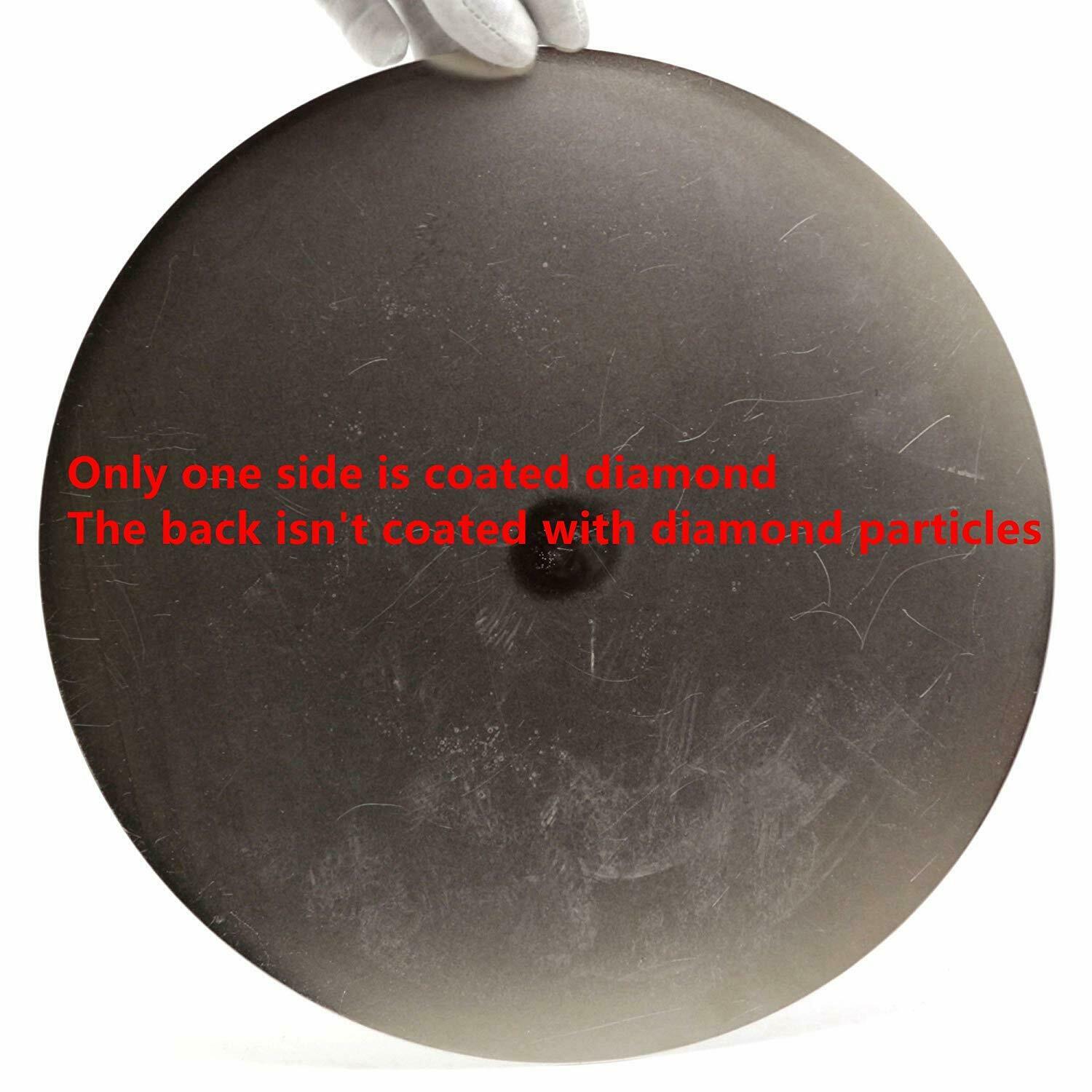

Arbor hole: No Center Hole, completed filled with diamond including center position; Only one side is coated diamond;

The diamond discs are one of the finest discs manufactured for Hobby, Lapidary, Glass applications;

Suitable to grinding gemstone, jewelry, glass, rock, carving knife, etc...

Recommended for rough and fine grinding

on faceting material plus general lapidary grinding when precision is required

Product Specification:

Grit: 60/100/600/1000

Grit type: Coarse-Medium-Fine

Diamond coating surface area : almost 100%,only one side is coated diamond

Wet use recommended

They are absolutely flat and parallel to meet the most exacting faceting requirements

Installation Recommendations:

Step 1. Sanded and cleaned the back of the disc firstly

Step 2. Used industrial strength self adhesive Velcro strips 2 inch strips

Step 3. Trimmed to the shape of the disc, then applied velcro to the machine base

The diamond disk is be coated fine diamond particle, the surface of the disks will havea a few floating diamond sand. The floating diamond sand is a few coarser grit diamond particle and nickel is be coated on the surface,but it is be fixed not strong, it is easy to remove

Some our customers tell us when their receiving the new fine-grained disk, usually using scrap glass polishing a period of time, remove the floating sand firstly, and then normal grinding the glass and gemstone. We also recommend that you try to use the same method